Introduction

The Tóth Metál Bt. is a full Hungarian small enterprise owned by my family for 2 generation and located 120 km far away from Budapest, 20 km from Eger in Sirok.

The beginings are dating back to 1970s. It started with Senior László Tóth thoughts in a 50 m2 place. Firstly the main profile was to produce fasteners, screws, nuts, fittings and metal ware.

The changing started in 1992 when Jr. László Tóth and his wife lead the company into a dinamically developing small enterprise. Instead of the old workshop, today, we produce on a 3300m2 area with a 1000m2 big, modern, air-conditioned factory. The main profile is the production of precisely silvered parts which are made on our tradicional machines as well as 14 modern CNC controlled turning-machine and shaping-machine center in a 2 or 3 shifts work schedules.

In our co-workers you can find well-experienced labours as well as young experts opened for the development. The usual statical manpower is 16-18 person. Our customers mainly Western-Europian and Hungarian multinationalist medium and small enterprises.

The main products are automotive parts, machine-building parts, military industry, axes, bushings, fittings, drop forging tools. We also furbish them. Parts of auxiliary engines, custom made rollerchains, special filling and surfacing welds. On our machines custom small and middle serial parts are made with the help of computer model or based on technical drawing.

Bemutatkozás

In the recent years one Siemens NX9 CAD-CAM software was bought that gives us the ability to recieve 2D or 3D models from different CAD-CAM systems and create the CNC program that is needed for the processing eliminating the errors during the production and shorten the deadlines. With the help of this software we got the chance to the procession of high-speed, high-precision, complex-surfaced workpiece, which can be done with our modern, suitable CNC controllers and machine.

In 2006 we introduced the ISO 9001:2000 quality assurance system that was renewed in 2009 as of the ISO 9001:2009 standard and it is review every year. One performance expert take care of the supervision and the function of the system.

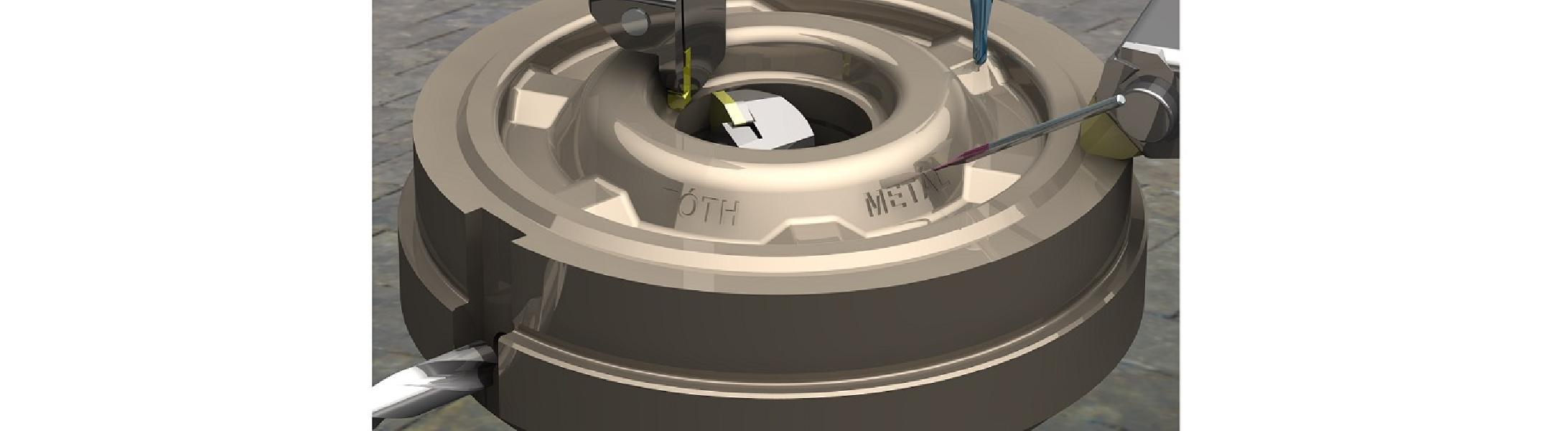

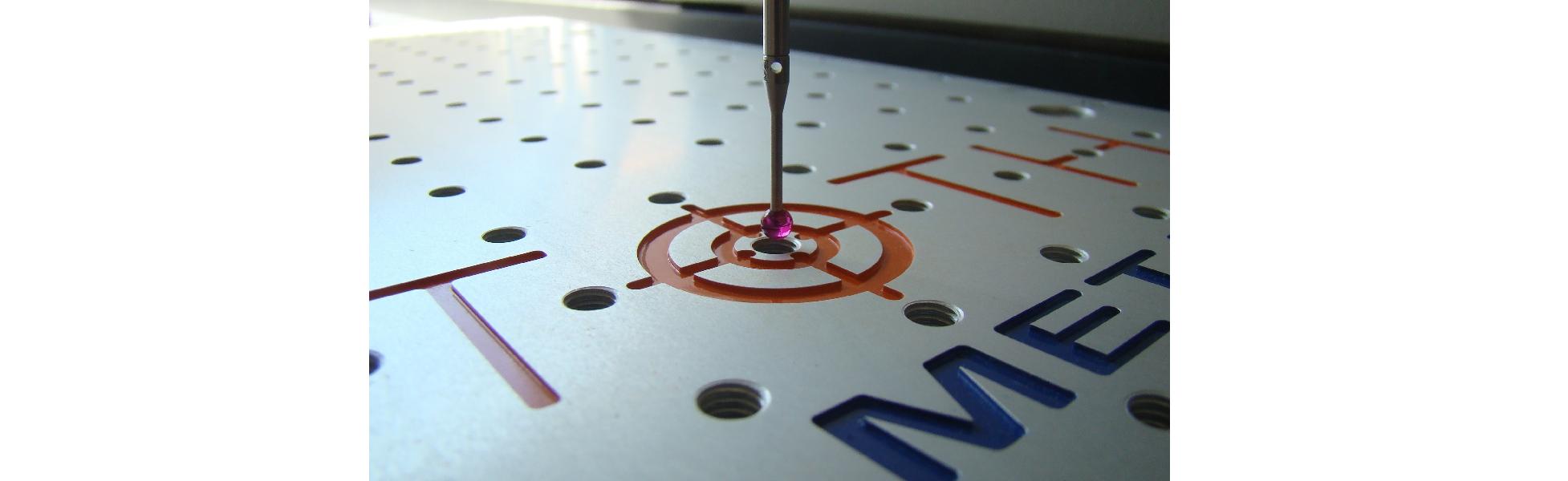

In 2015 we get one up-to-date 3D 5 axled COORD 3 ARES 10.7.5 CNC mearusing machine that with we can contract custom measurements in an air-conditioned measuring room. Our destionation is to meet the market expectations in the most effective and competitive way.

For this purpose, I develop my machines, the technical terms and the working confitions.

Yours faithfully,

Tóth László

Executive Directory

Owner